3D printed, hand painted

With a little effort, and with some inexpensive supplies, decent looking miniature figures can be produced with a filament printer.

I found two open-source models of pterosaurs on Thingiverse. There are many other miniature files available at that site.

The supplies I used are easily available and inexpensive. (Most of the tools came from a dollar store.)

Materials used

For this model I used latex miniature paints. These paints can be found at hobby stores or comic book stores. They are designed for brush painting, are water soluble, and easy to clean up.

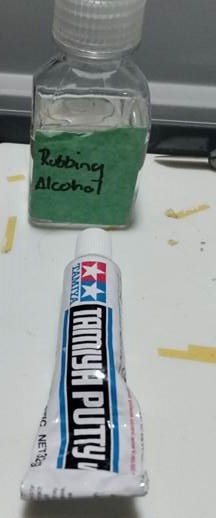

Model putty. This product comes in small tubes and can be cleaned up with rubbing alcohol. It is used to fix holes or rough spots on the printed object. Available from hobby stores.

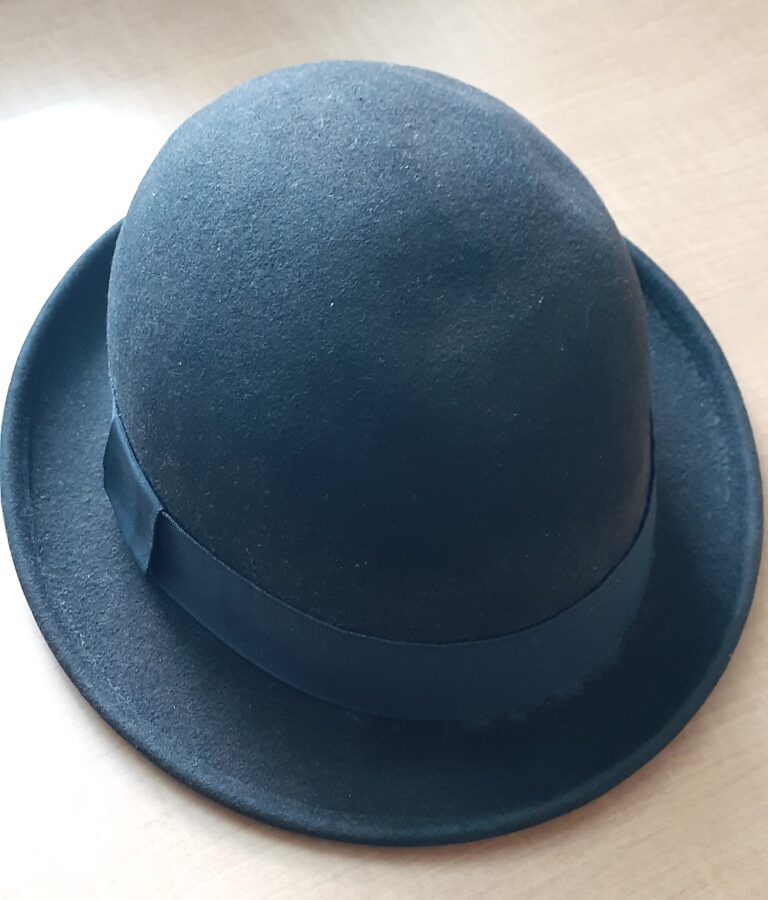

Hobby knife, large nail clippers, sanding film, and nail sanding sticks are all available at any dollar store. They are used to clean scrap plastic off the printed object, and to smooth out rough spots. Dollar store cyanoacrylate glue (crazy glue) was used to attach the finished figure to a base.

Printing

I downloaded the STL files from Thingiverse and loaded them into Cura. I resized the Geosternbergia to fit. (I chose 8 centimeters as the longest dimension.) Because of its outstretched wings the Geosternbergia model needed supports added. Luckily Cura can do this for you. The supports consisted of a thin layer of PVA (Polyvinyl Alcohol – a clear water-soluble material) and then PLA (polylactic acid) was used for the remainder of the supports.

The print quality was vs the standard at 0.2. The job took about 45 minutes to complete.

The sitting pterosaur model did not need supports. I loaded the STL into Cura and printed it without any adjustments. The print quality was set to 0.1. The job took about 40 minutes to complete.

Cleaning

The Geosternbergia printed with a large amount of support structure. That had to be removed first. The entire piece was soaked in warm water for about 30 minutes. This softens the PVA enough to start prying the model away from the supports. This is the most time-consuming part of the process. A word of caution – if the water is too hot the plastic can soften and deform. I did bend one wing, but used more hot water to soften the wing and correct the shape. A hobby knife and clippers are essential to cut away parts of the support structure.

The pterosaur model had no support structure and only need to a hobby knife to cut away any residue. A nail sanding stick was used to clear any rough edges.

The Geosternbergia printed with a large hole in one wing. Model putty was used to fill the hole. This putty is soluble in rubbing alcohol and so a small amount of alcohol on your finger will help smooth the putty down nicely. The less putty you use the less sanding will be required later.

Sanding film and nail sanding sticks were used to clean up the dried putty and any imperfections left over from the printing process.

Painting

Latex paints do not adhere well to plastic. The finished pieces were painted with a latex primer paint. This was allowed to dry for two hours. Then latex paints were used for the final finish.

These links were helpful in offering advice while painting my models.

A stand was created for the Geosternbergia out of a piece of scrap plastic. The sitting pterosaur was glued to a small pebble. In both cases cyanoacrylate glue was used to permanently connect the model to the base.

The finished product and final thoughts

Excluding the printing time it took about 5 hours of time to clean up the models and paint the pair. Most of this time was spent removing the Geosternbergia from the supporting scaffold. The pterosaur in comparison only took about 30 minutes to clean up. Delicate or tricky structures can be made with an extrusion printer, but you will have to spend extra time cleaning up the models. I was happy with the result, and you will have to take my word for it that the figures look better on a display shelf than in an extreme close up.